The Customer

A global OEM of landscaping and ground care equipment for commercial and

residential applications.

Taking Over Supply

WCI previously provided a large amount of stock parts from our Midwest locations to support the customer’s factory in the Southeast. As the relationship grew, WCI opened a new location in proximity to the customer’s Southeast factory to provide additional levels of support.

Background & Situation

The customer was dealing with significant space constraints due to substantial amounts of on-hand inventory, as well as material handling costs and the time associated with repacking parts for lineside assembly.

- No room for maintaining the quantities of inventory necessary

- High and inconsistent handling costs

- Wasted time preparing supplies and parts for the assemblers

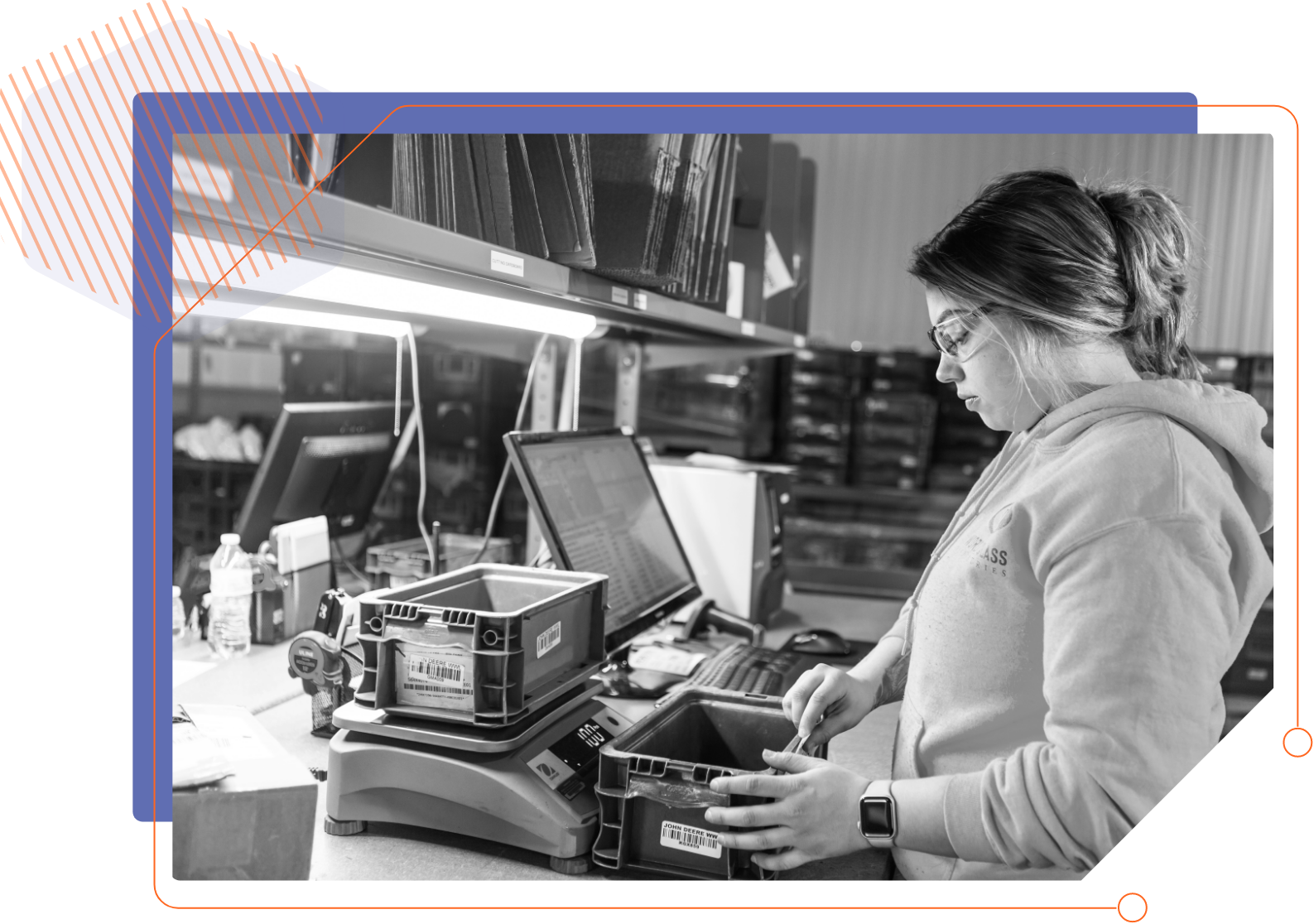

WCI Solutions

By taking on the supply management process at our Supply Chain Integrator site, WCI was able to free up factory floor space and time and reduce overall costs.

- Switched shipping from bulk repacks to smaller scale individual repacking for lineside needs, reducing client’s handling costs.

- Moved all stock parts to daily triggers rather than pre-scheduled shipping dates.

CASE STUDY RESULTS

Standout Achievements

Our goal is to make your job easier by taking on the tasks that prevent you from achieving maximum efficiency.