Our History

We have constantly developed our offerings and continued to refine proven processes such as integrated procurement, data-rich assembly, customized order fulfillment, and and consistent project management. This combination has allowed us to deliver comprehensive manufacturing solutions for global original equipment manufacturers and small-to-medium enterprise product companies for over half a century.

Our Services

We’re proud to serve global OEM’s in the agriculture, construction, powersports, power generation industries and more. We also create End-to-End solutions for small-medium sized companies in the product manufacturing space.

Learn More

ORIGINAL EQUIPMENT MANUFACTURERS

We provide a wide array of assembly, kitting and procurement services. Our supply chain integration capabilities allow us to take on ownership of the supply chain and deliver seamless assembly, kitting and parts fulfillment solutions designed to solve your toughest challenges.

END-TO-END

For small to medium sized product manufacturing companies, we take on your entire supply chain and product assembly process, becoming your single point of contact. Think contract manufacturing, only better.

Success Through Shared Purpose and Vision

We’ve built strong relationships with great customers in many unique industries all over the world: customers with vision and purpose. Each day, WCI’ers work throughout locations in the USA and Europe to help our customers achieve their brand promise.

Customer Satisfaction

What might seem simple and straightforward can be incredibly complex to accomplish given system, space and supply chain configuration. WCI is up to this challenge and enables you to serve your customers with excellence and delivers your brand promise.

Dynamic Markets

Circumstances change… reacting quickly and effectively can be the difference between missing production schedules, or achieving forecasts and growing your market share.

Infinite Complexity

Today, coordinating the procurement, assembly and fulfillment of products is complex. Tens of thousands of components from thousands of suppliers flow through our facilities every day. Our team-driven process helps you focus on what you do best.

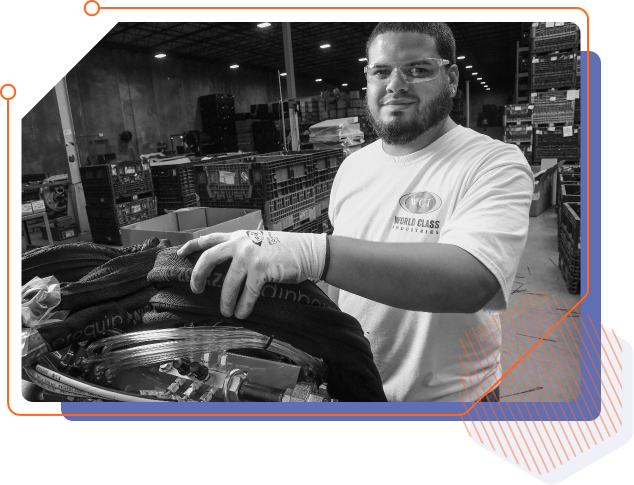

The Right People

At WCI, our ability to add value begins with a strong emphasis on the recruitment of strong candidates, selection of top performers and development of a dynamic culture.

WCI’ERS

More than 260 strong, our WCI’ers are values-driven individuals working in various roles across ten locations to deliver results for our customers.

A-PLAYERS

We focus on the recruitment, development and retention of individuals in the top 10% of available talent who are consistently identified as high performers.

JOIN US

World Class Industries is always looking for top achievers to join our team. Visit our careers page to learn more about current opportunities.

HOW WE SUCCEED

WCI’s unique approach is critical to the success of our customers. From how we are structured and approach the work to the alignment of our long-term goals, we are optimized to deliver our customers an exceptional advantage.

-

VALUES DRIVEN

How we work together, collaborate with suppliers and align with customers is guided by our values: agile, genuine, and team-driven.

-

FAMILY OWNED

Still under the same family ownership, our commitment to creating value for customers is firmly understood and shared throughout the company.

-

PRIVATELY HELD

Our privately held ownership allows us to weather all manner of market conditions and deliver long-term stability for our customers.

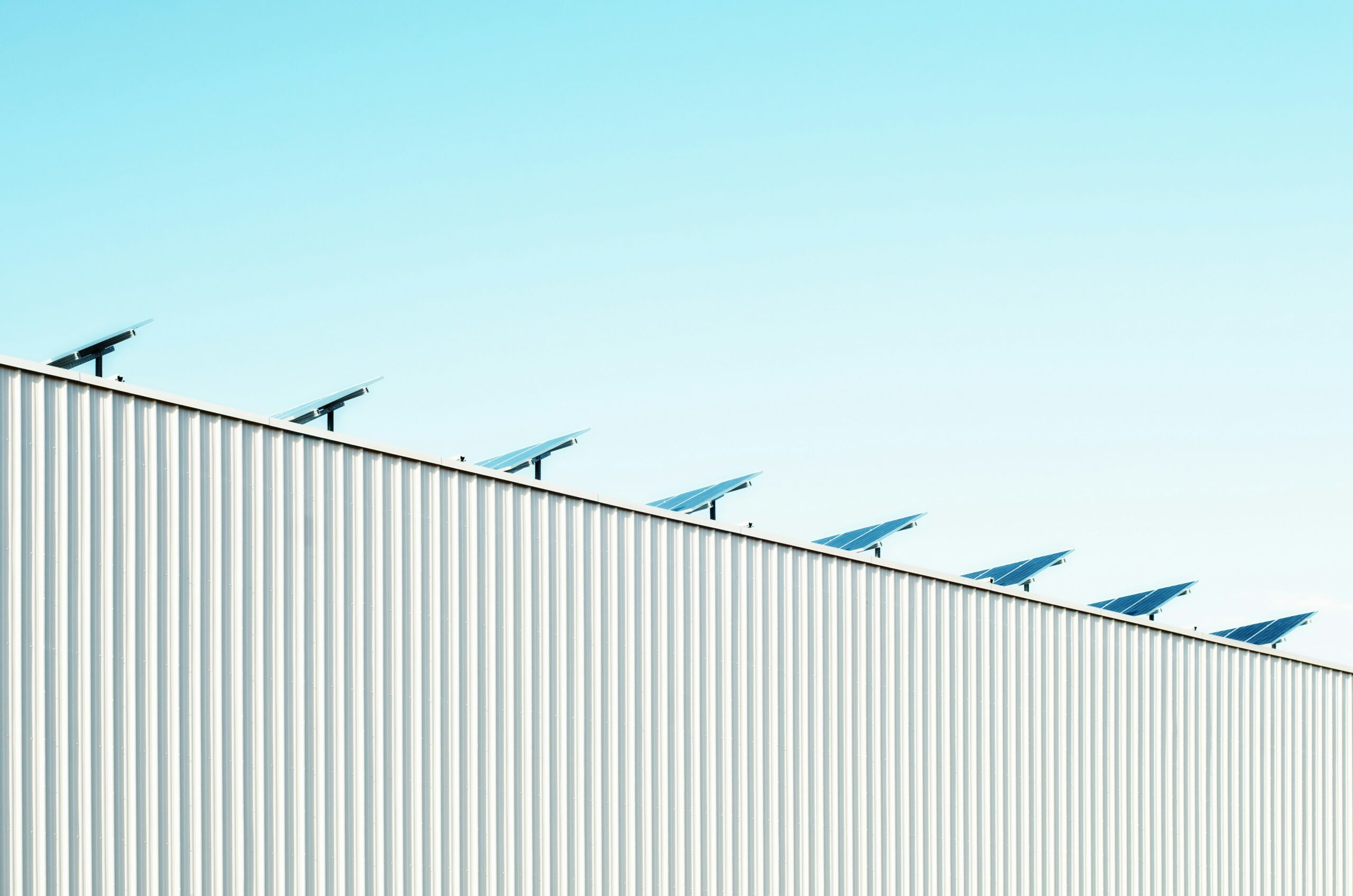

Sustainability at WCI

At WCI, and across our 10 facilities, we are dedicated to making a positive impact on the environment through our comprehensive sustainability initiatives. We proudly employ electric fork trucks, harness the power of solar panels, and actively strive to limit the impact of dunnage through recycling. In 2024 our dedication extends to maintaining low CO2 emissions, contributing to a greener, more sustainable future.

-

665

Metric Tons CO2 Emissions

-

37

Electric Fork Trucks

-

4

Facilities Utilizing Solar Panels

-

61

Tons of Cardboard Recycled

The WCI Way Has Real Impact on Our Customers

We are proud of the impact we have had on our customers and the recognition we have earned along the way.