The Customer

A global agricultural OEM was seeking help in improving the safety, efficiency and space utilization of the production line in their factory.

Improving Safety and Efficiency

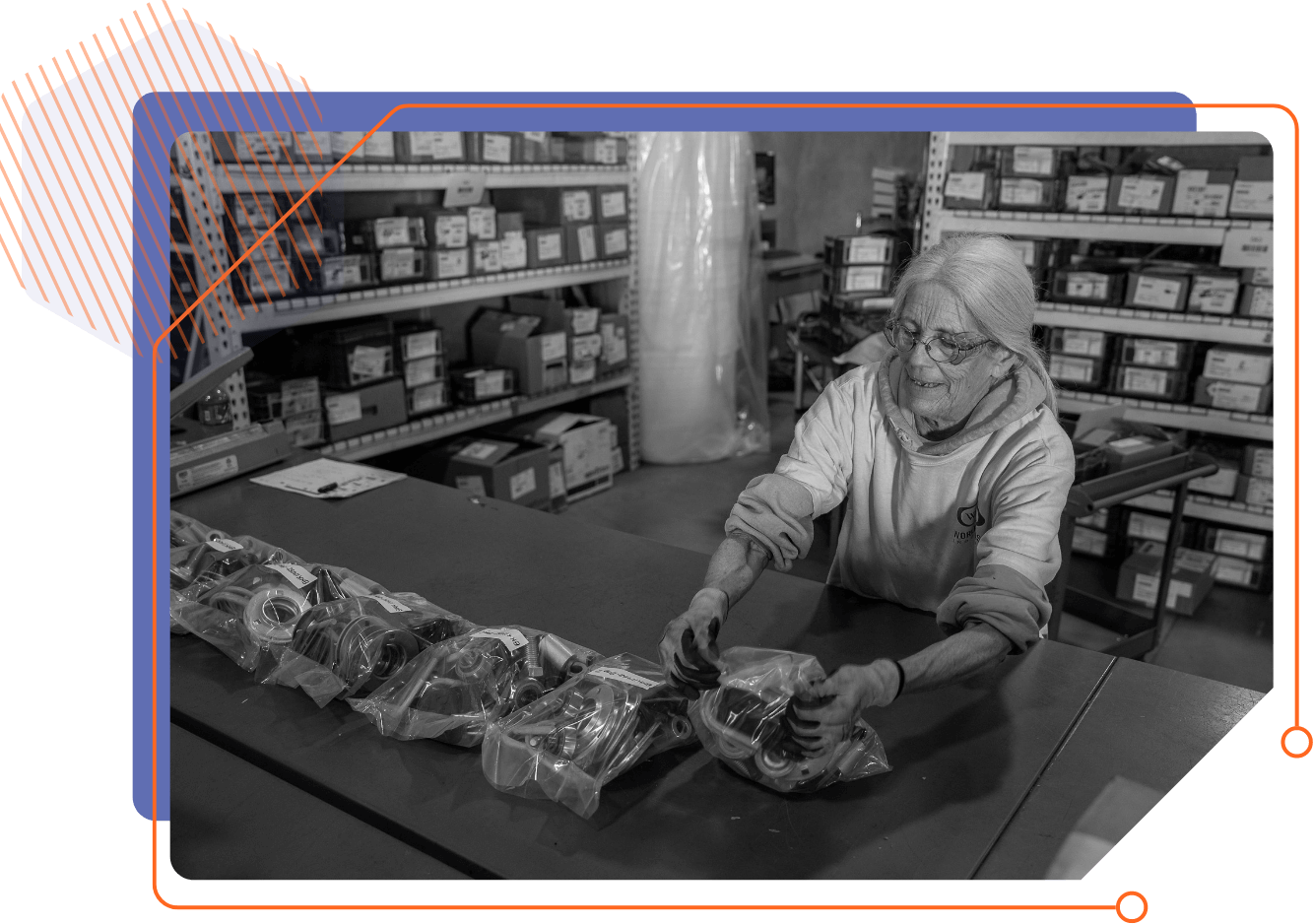

WCI partnered with the customer to deliver a kit-to-build and sub-assembly solution.

Background & Situation

During WCI’s analysis, we uncovered opportunities to provide the technicians with a safer, more efficient way to assemble the sprayer that wouldn’t require them to climb on and off the equipment.

- The technician had to climb on and off the sprayer several times in order to install various components.

- Due to all of the various sub-components, a significant amount of line-side space was being consumed for parts storage.

WCI Solutions

Sometimes a simple problem holds many opportunities for improvement. With the sprayer project we were able to provide kitted parts to our customer’s production sequence that shortened build times and enhanced overall safety. WCI also utilized technology to ensure quality control and improved kit presentation to the factory.

- Repacked and kitted parts for more efficient assembly.

- Redirected parts to our Des Moines facility for warehousing, freeing up square footage for the client’s integrator partner.

- Advanced ERP system allowed assemblies to be broken into sub-kits and sub-assemblies.

- Improved weight scale capabilities in ERP system to trigger a warning if a sub-kit is over or under the correct weight.

CASE STUDY RESULTS

Standout Achievements

WCI looks beyond the simple solution to the opportunities within the system to our clients make better products faster and with optimal safety.