The Customer

A company focused on the creation of game-changing solutions for personal air quality, surface decontamination, commercial and residential deodorizers, and engineered solutions.

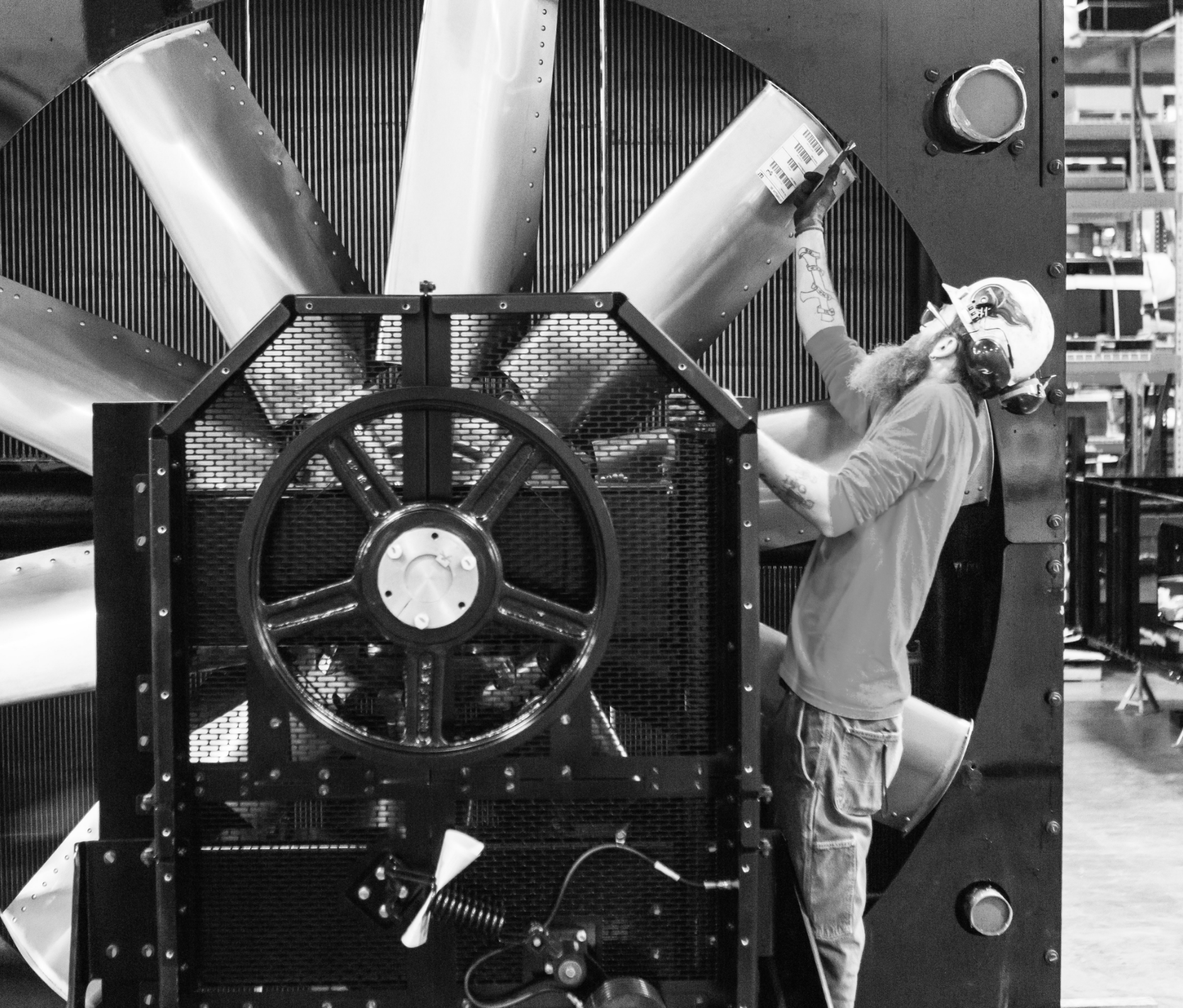

Taking Control of What Others Can't

Our customer, a small-to medium-sized product innovation company, was unable to scale due to supplier constraints. They simply didn’t have the time, resources, or partnerships to handle it alone.

Background & Situation

The customer was going through explosive growth due to the pandemic environment. As a result, they experienced serious supply chain issues with their current manufacturing partner, preventing them from realizing their growth potential.

- Supplier was high in cost and failing to deliver on time

- Internally managing both suppliers and assembly

- Non-optimized supply chain

WCI Solutions

By increasing capacity and resolving supply chain inefficiencies, we were able to help accelerate our customer’s success.

- Doubled the customer’s throughput

- Provided an increase in profit per unit, safety improvements, supply chain simplification, and project management

- Utilized global supply base to bypass distributor pricing

- Dual-sourced components to ensure product availability

- Identified electrical and metal fabrication design enhancements to improve manufacturability

CASE STUDY RESULTS

Standout Achievements

From doubling capacity and providing a bill of material efficiencies to improving product safety and simplifying supply chain complexities, we helped our customer increase production and make more money.