The Customer

Leading global manufacturer of construction and mining equipment, diesel and gas engines and industrial power generation equipment.

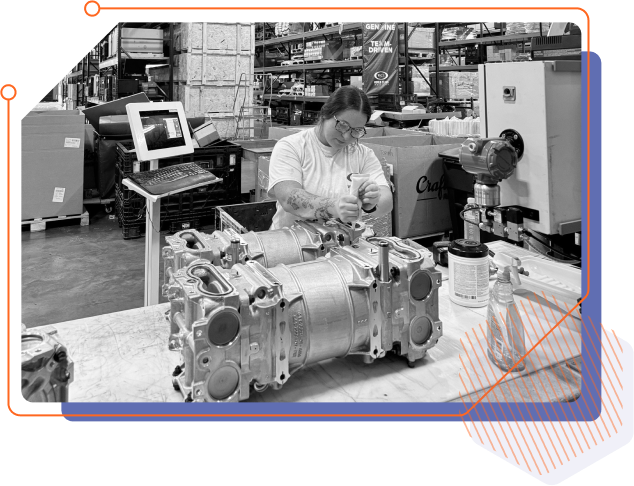

Leveraging WCI Technology and Engineering Expertise

WCI embraced the challenge of a complex filter system design, surpassing customer expectations at every step and proving our ability to deliver excellence.

Background and Situation

Our customer, challenged by a significantly compressed timeline, created a game changing solution to reduce methane emissions by 20% to meet EPA-driven climate related initiatives. They selected WCI based on our unique capabilities to combine innovative assembly technologies with complex build processes, including testing, serialization, and assembly data tracking.

- Methane emission tax introduced through the 2022 Inflation Reduction Act, with end-customer impact in 2025

- Accelerated product launch drove a need for outsourced assembly

- The customer required a turnkey assembly partner, capable of delivering on-time and with exceptional quality

WCI Solutions

Combining internal expertise with customer collaboration, WCI delivered a complex, process-based assembly solution.

- Custom WCI fixturing, test system, and process to detect presence and precise location of parts, and ensuring leak test conformance

- Implemented multi-axis light curtains to ensure safety during actuator press applications

- Designed and engineered a laser-guided cup plug pressing station utilizing actuators

- Paired state-of-the-art technology with a new user friendly intuitive Human Machine Interface (HMI)

- One point of contact to manage complex global supply base

CASE STUDY RESULTS

Standout Achievements

Through WCI’s proactive project management and use of advanced technologies, we helped our customer bring their new proprietary system to market in under 12 months.